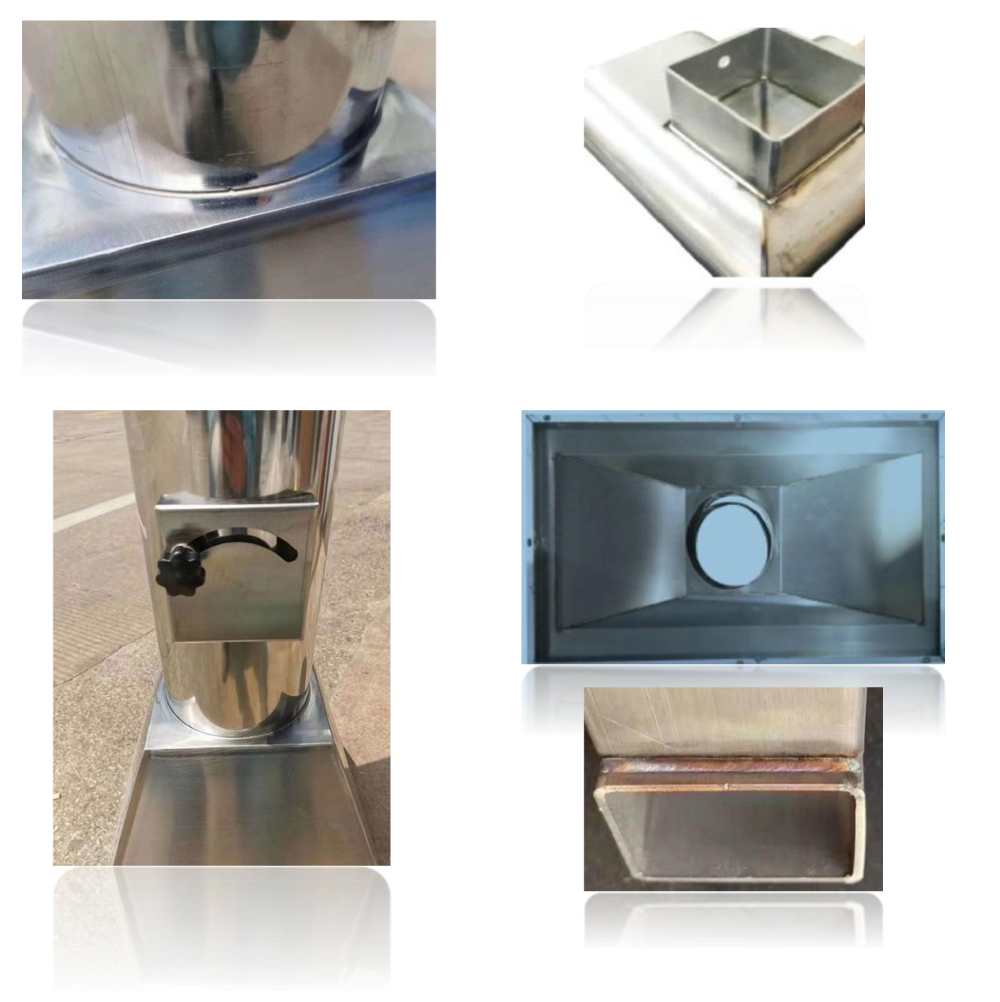

Handheld fiber laser welding machine SF1000HWM is used to weld metal plates and metal tubes.

The fiber laser welding machine couples the laser beam to the optical fiber, after long-distance transmission, and then converts it into parallel light through a collimating mirror, and finally focuses it on the welding spot area between the work-pieces, producing this way a beam of high-intensity that is concentrated into one spot.

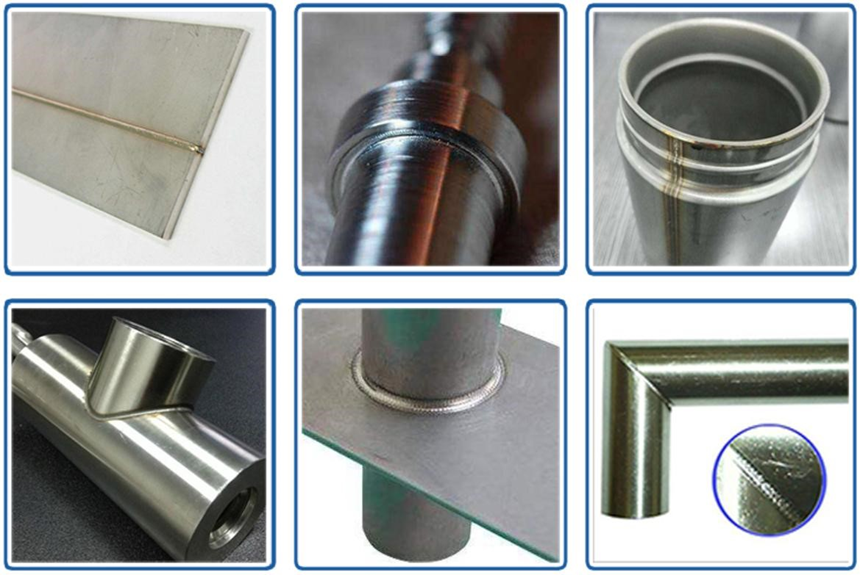

This concentrated heat source enables fine, deep welding and high welding speed off all kinds of metal. The welding seam is discreet and firm.

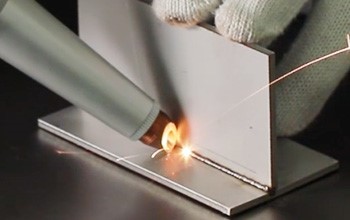

Non contact welding.

The non-contact method is adopted for the difficult parts making the optical fiber laser welding more flexible.

Laser beam achieves the separation of time and energy, and multi-beam processing makes welding more accurate.

For more information please fill the inquiry form

Guarantee

2 Years

Support

All Over Greece

Guarantee

2 Years

Support

All Over Greece

DESCRIPTION

| Models | SF1000HWM φορητό fiber laser welding μηχ/μα |

| Laser Power | 1KW / 1.5KW |

| Laser wavelength | 1080nm |

| Welding speed | 0-120mm/s |

| Largest welding gap | ≤1/10 του πάχους του φύλλου μετάλλου |

| Welding range | 0.5~4mm ανθρακοχάλυβας,0.5~4mm ανοξείδωτο ατσάλι,0.5~2mm αλουμίνιο,0.5~2mm μπρούτζος |

| Source types | RAYCUS (China) SENFENG (China) IPG (Germany) |

TECHNICAL SPECIFICATIONS

| Fiber cable length | Standard 10m |

| Cooling mode | Water cooling |

| Electromechanical | 380V/50HZ |

| Consumable | Συγκόλληση με Άζωτο, πίεση εξόδου 0.2Mpa |

| Total power | 8KW |

| Dimensions | 1300X650X1100mm |

| Total Weight | 375KG |

ADVANTAGES

Flexibility

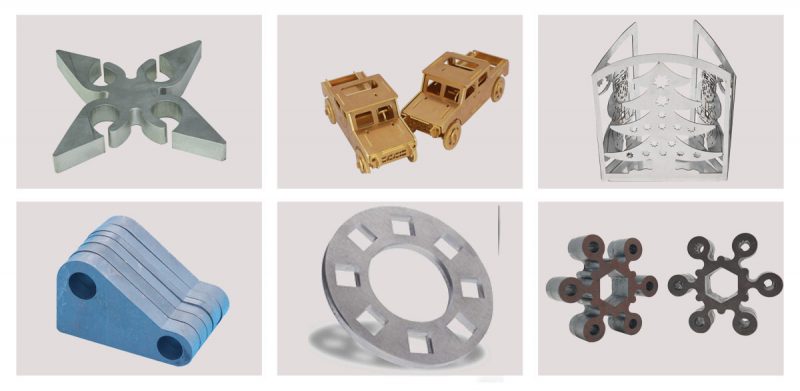

It’s suitable to weld any shaped products

High Efficiency

The welding speed is 2-10 times faster than the traditional welding processing speed

Compatible with a wide range of consumables that can be changed over easily and quickly.

High Welding Quality

Smooth welding seam, without subsequent grinding, saving time and cost.

No distortion, no welding scar, and very strong welding seam.

Modular compact design

Compact design with replaceable modules takes less, layout space, and provides easy maintenance.

Low Cost

80% to 90% power savings, processing costs are reduced by 30%.

Simple Operation

The operator can get started quickly even without any experience.

Flexibility

The portable fiber welding machine can meet the requirements of square tube welding, round tube butt welding, plate tube welding,etc. The machine can be customized for all types of tooling as for example with copper wire feeding mechanism and nozzle.

ΜΕΘΟΔΟΙ ΣΥΓΚΟΛΛΗΣΗΣ

Κάθετη Συγκόλληση

Παράλληλη Συγκόλληση

Συγκόλληση με ράμμα χαλκού