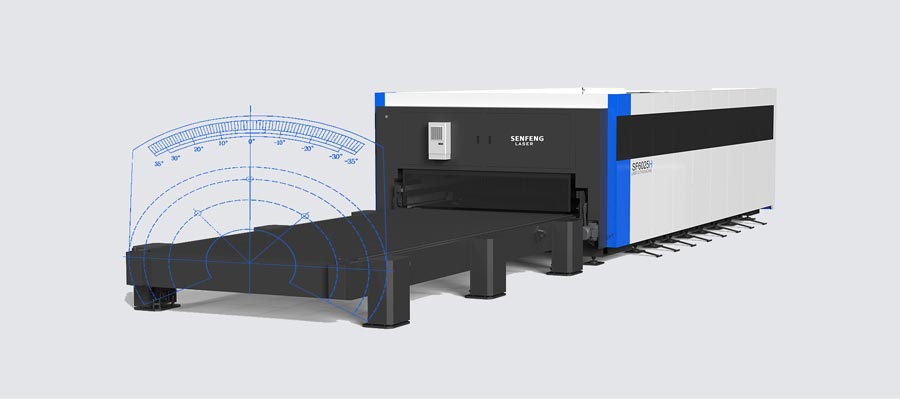

SF6025H5 ultra high power fiber laser cutter is a kind of metal cutting laser machine. Equipped with fiber laser device with laser power from 8kw to 36kw, it runs stably when cutting medium and thick steel plate. And the working area up to 12050*2530mm can be chosen.

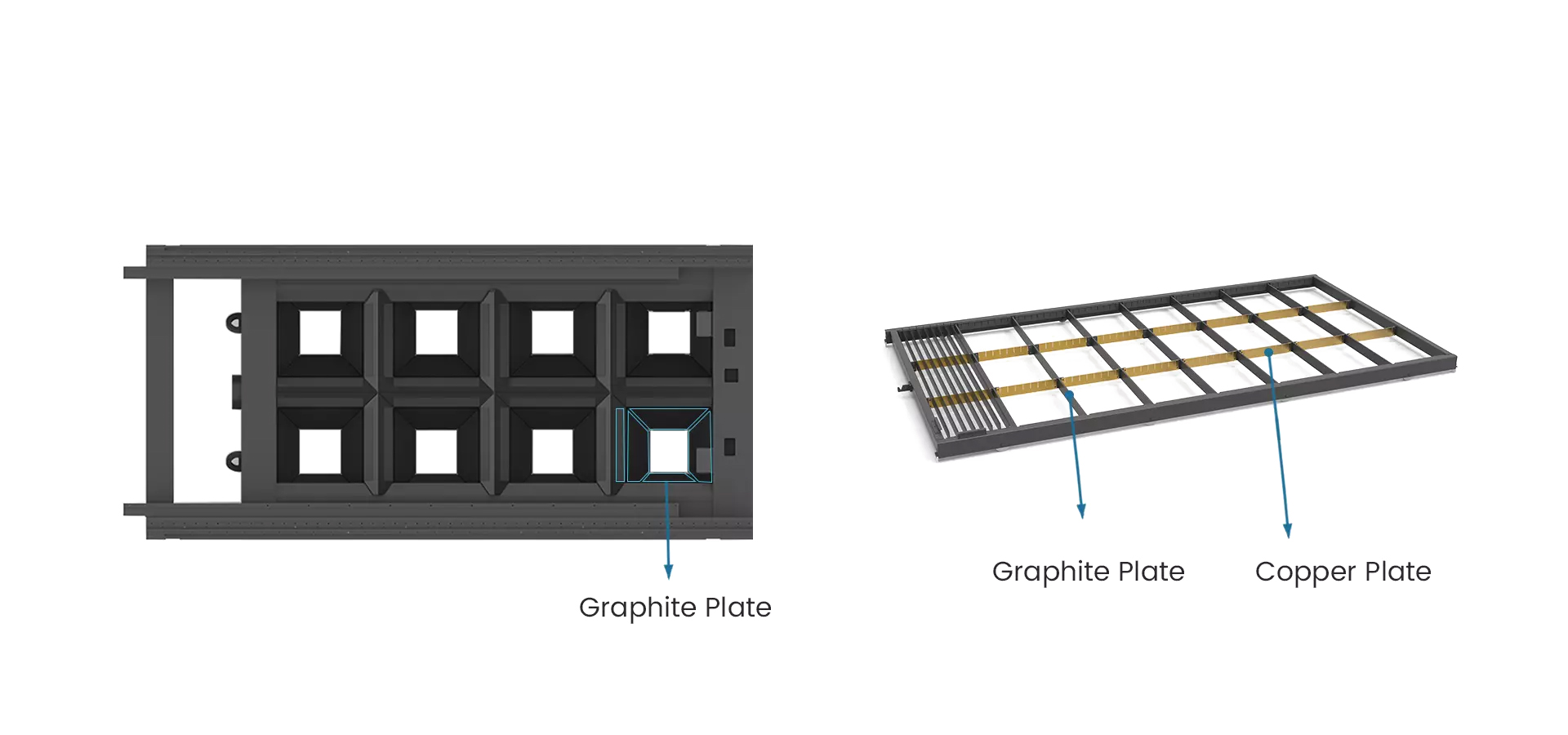

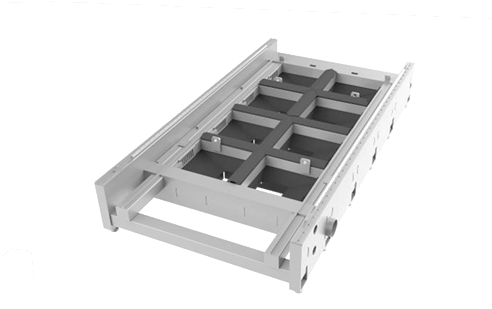

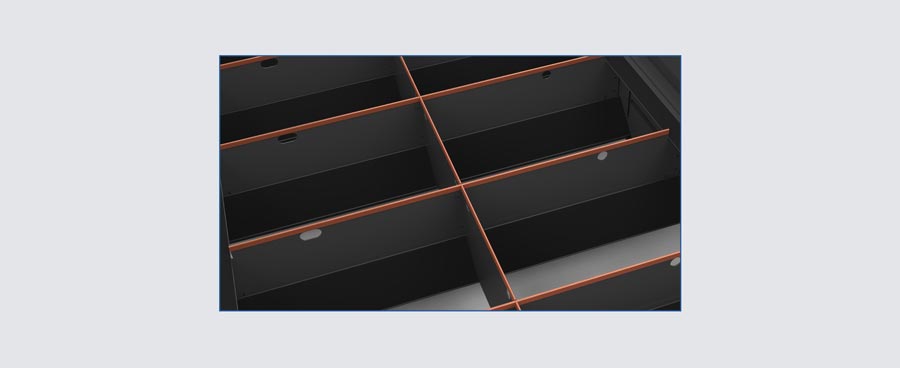

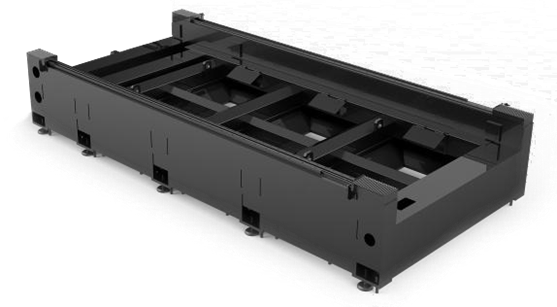

The heavy-duty frame bed is adopted with stable structure, small deformation, and can withstand higher acceleration. The detachable funnel is equipped with graphite plates and red copper to avoid thermal deformation of the bed and increase the service life of the equipment.

The heavy-duty frame bed is adopted with stable structure, small deformation, and can withstand higher acceleration. The detachable funnel is equipped with graphite plates and red copper to avoid thermal deformation of the bed and increase the service life of the equipment.

Guarantee

2 Years

Support

All Over Greece

Guarantee

2 Years

Support

All Over Greece

ΠΕΡΙΓΡΑΦΗ

| Model | SF3015H5/SF4020H5/SF6020H5 SF6025H5/SF8025H5/SF12025H5 |

| Working Area(mm) | 3050* 1530/4050 * 2030/6050* 2030 6050* 2530/ 8050 * 2530/12050* 2530 |

| Working Area(in) | 120*60/159*80/238*80/238*100/317*100/ 474*100 |

| X-axis Travel | 1530mm/ 2030mm/2530mm |

| Y-axis Travel | 3050mm/4050mm/6050mm/8050mm/12050mm |

| Τύπος πηγής | IPG (Germany) |

| Laser Power | 8KW/10KW/12KW/36KW |

| Maximum Speed | 200m/min |

| Maximum acceleration | 2.8G |

| X/Y Axis positioning accuracy | ±0.05mm/m |

| X/Y Axis repeated positioning accuracy |

± 0.02mm |

Cutting materials

Carbon Steel, Stainless Steel, Galvanized, Zinc Steel, Aluminum, Bronze, Copper, etc.

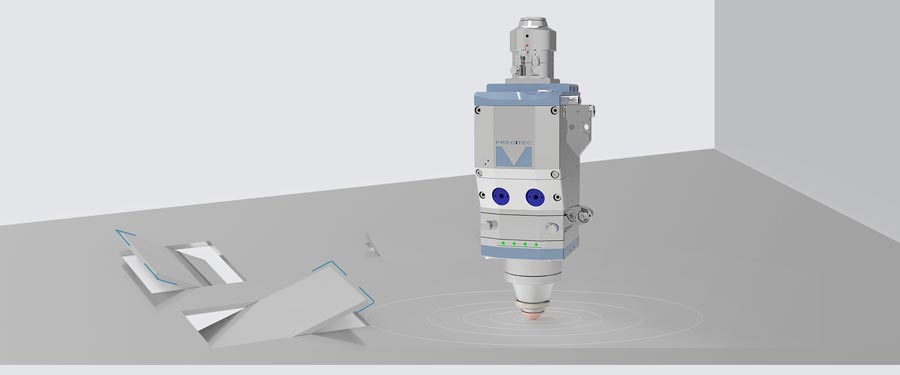

Autofocus Laser Head

Laser head with reinforced cover, resilient in high pressures, automatic control system and intelligent barrier avoidance system to ensure cutting quality and longer lens life.

Autofocus Technology

Suitable for various focal lengths, the focus will be adjusted automatically during the cutting process, which can achieve the best cutting effect of different thickness of metal sheet. Laser head actively avoids obstacles, greatly reducing the probability of the laser head hitting the board.

The laser head adopts air cooling and water cooling. Air cooling can ensure a constant temperature of the cutting nozzle, water cooling can prevent heat transmission to the optical lens, and double insurance can ensure stable and efficient cutting.

The laser head adopts air cooling and water cooling. Air cooling can ensure a constant temperature of the cutting nozzle, water cooling can prevent heat transmission to the optical lens, and double insurance can ensure stable and efficient cutting.

For cutting 6mm or more carbon steel thickness, the laser autofocus reduces the drilling time by 1/2, for cutting 16mm or greater the drilling time will be reduced by 2/3.

The laser head adopts air cooling and water cooling. Air cooling can ensure a constant temperature of the cutting nozzle, water cooling can prevent heat transmission to the optical lens, and double insurance can ensure stable and efficient cutting.

The laser head adopts air cooling and water cooling. Air cooling can ensure a constant temperature of the cutting nozzle, water cooling can prevent heat transmission to the optical lens, and double insurance can ensure stable and efficient cutting.

For cutting 6mm or more carbon steel thickness, the laser autofocus reduces the drilling time by 1/2, for cutting 16mm or greater the drilling time will be reduced by 2/3.

Intelligent obstacle avoidance

The laser head has sensors in order to recognize and actively avoid any object is higher than the nozzle, greatly reducing the probability of the laser head hitting the sheet or tube.

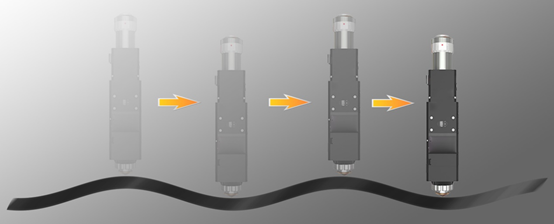

Automatic Focus Height Guide

- A U.S.-imported technology patent that has been adopted and improved by China.

- The automatic sensor understands the capacity between the edge of the isolated nozzle and the surface of the cutting sheet and channels the data to the height monitor.

- If the metal sheet has ripples on its surface, the focus height guide can ensure a constant distance between the focal lens and the respective level of the metal cutting sheet so that consistent cutting quality can be achieved.

- Therefore this technology can avoid defects caused by wavy metal surfaces and also avoid any damage that may be caused to the head nozzle.

Special head protection cover

Conductive in observing infrared light, better heat dissipation, internal gas path offering better combustion.

Intelligently synchronized hydraulic elevator platform

Adopts 6 sets of large and small oil cylinders, intelligent automatic synchronization, stable operation, synchronization error ≤1mm, lifting weight up to 30 tons.

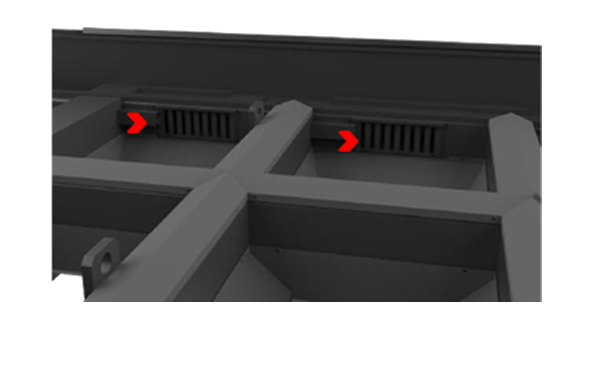

Graphite, copper protection(≥8000w)

The thermal conductivity of graphite is poor, which effectively prevents the machine bed from being deformed by heat and guarantees the service life.

Laser Head Advantages

- The fully upgraded design to avoid dust entry and the double layer protection minimize the risk of lens contamination.

- The disk type focus can be adjusted manually. The setting is accurate and flexible. The adjustment range is up to 20mm and the accuracy 0.05mm.

- It has a variety of fiber optic interfaces and can be customized to all kinds of fiber laser.

- Both the concentration lens and the focus mirror and nozzles have a cooling structure.

- Τα μηχανήματα Fiber laser της εταιρείας SENFENG εξοπλίζονται από 3 διαφορετικούς οίκους κεφαλών: SENFENG (China), Raytools (Switzerland), Precitec (Germany)

- SENFENG’s fiber laser machines are equipped with 3 different head companies: SENFENG (China), Raytools (Switzerland), Precitec (Germany)

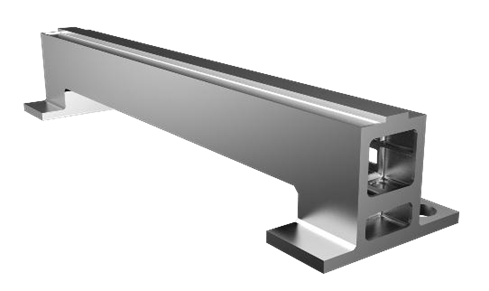

Cast Aluminum Beam

The Cast Aluminum beam offers high movement accuracy and maximum rigidity which are two factors that help to lengthen the life of the machine.

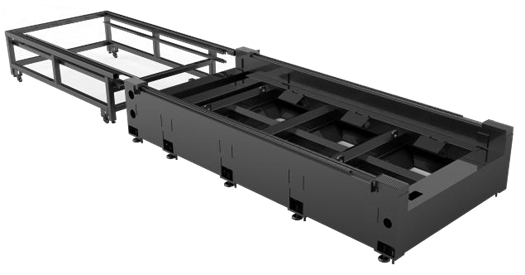

Double table with cutting sheet dauto-switching

Dual loading, unloading platform

Parallel Sheet Switching, Stability & Speed.

Parallel Sheet Switching, Stability & Speed.

Carbon Steel Special Design Table

The high quality cushioning protection of the table is due to the high precision welding with CO2 protection as well as the annealing & artificial aging treatment of the metal (thermal treatment at 600°C for 24 hours).

Table features:

High strength, good stiffness, long-term operation of the table without distortion, high processing accuracy.

Exhaust system

Double Upper and Lower Evaporation System for smoke absorption.

Table with fire-fighting Graphite coating

The fiber laser range of 4000W or more is equipped with a protective coating of burn proof graphite and copper coating, ensuring that the work table is not distorted by voltages and temperatures.