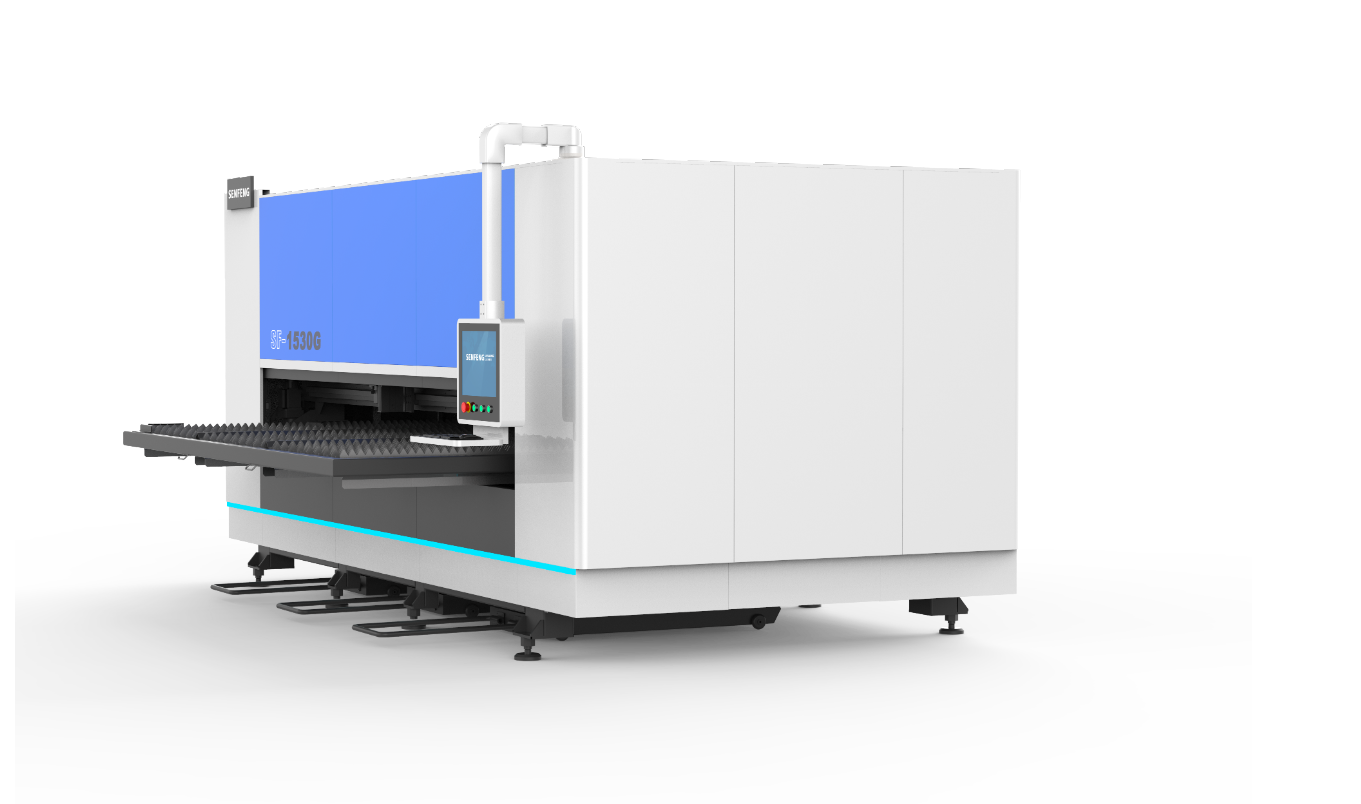

Compact Fiber Laser Εξοικονόμησης Χώρου

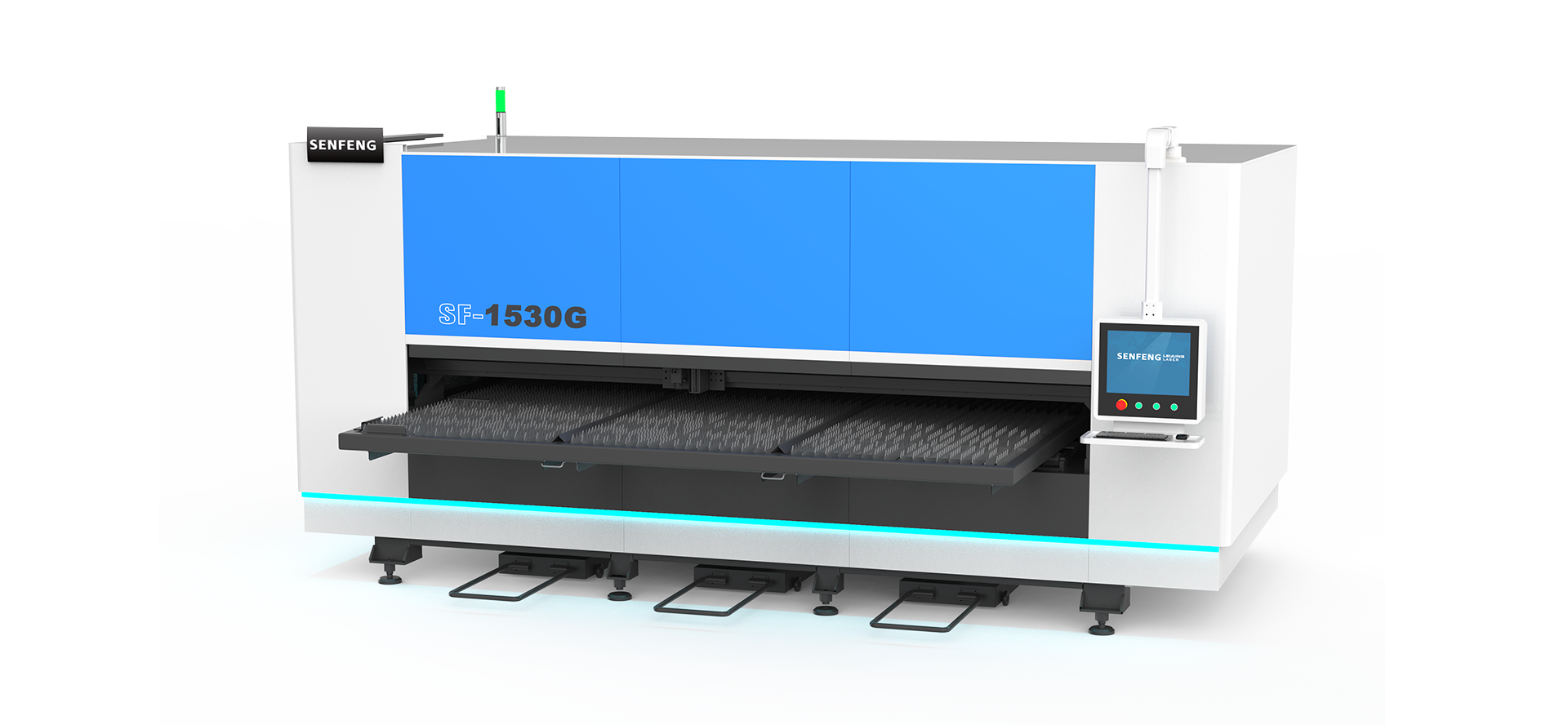

SF1530G is a fully enclosed space saver single table fiber laser cutter machine for cutting metal sheet.

It was upgraded on the basis of open type fiber laser cutting machine SF3015G.

The laser power is equipped with 1kw to 3kw.

SF1530G has a small footprint(4890*2300mm/192.52*90.55inches).

The fully enclosed structure and the partitioned dust removal system help reduce environmental pollution.

The pull-out platform is more convenient for loading and unloading materials.

The metal sheet laser cutter passed CE/FDA /ETL certifications, which is in line with European and American standards.

For more details, please fill in the form of interest.

Guarantee

2 Years

Support

All Over Greece

Guarantee

2 Years

Support

All Over Greece

DESCRIPTION

| Model | SF1530G |

| Working Area(mm) | 3000 * 1500 |

| X Axis Travel (mm) | 3000mm |

| Y Axis Travel (mm) | 1500mm |

| Z Axis Travel (mm) | 120mm |

| Laser Power (kw) | 1KW/1.5KW 2KW/3KW |

| Maximum Speed | 80m/min |

| Maximum acceleration | 0.8G |

| X/Y Axis positioning accuracy | ±0.05mm/m |

| X/Y Axis repeated positioning accuracy | ± 0.02mm |

Cutting materials

Carbon steel, Stainless steel, Galvanized steel, Zinc steel, Aluminum, Bronze, Copper and others.

TECHNICAL SPECIFICATIONS

| Auxiliary Gass | Nitrogen, Oxygen for Carbon Steel |

| Power Supply | 380v, 50hz/60hz |

| CNC Software | CYPCUT |

| Wave Length | 1.07 um |

| Beam Quality | <0.373 mrad |

| RAYCUS Source | RFL-C100, RFL-C1500, RFL-C2200 |

| IPG Source | YLS-K |

| Laser Head | RayTools or Precitec (With Autofocus) |

| Cooling System | TeYu CWFL-1000, CWFL-1500, CWFL-2000 |

| Linear Guide | XYZ Servo Motors: Schneider ή Delta Y 2x1500W, X 1x1000W, Z 1x400W |

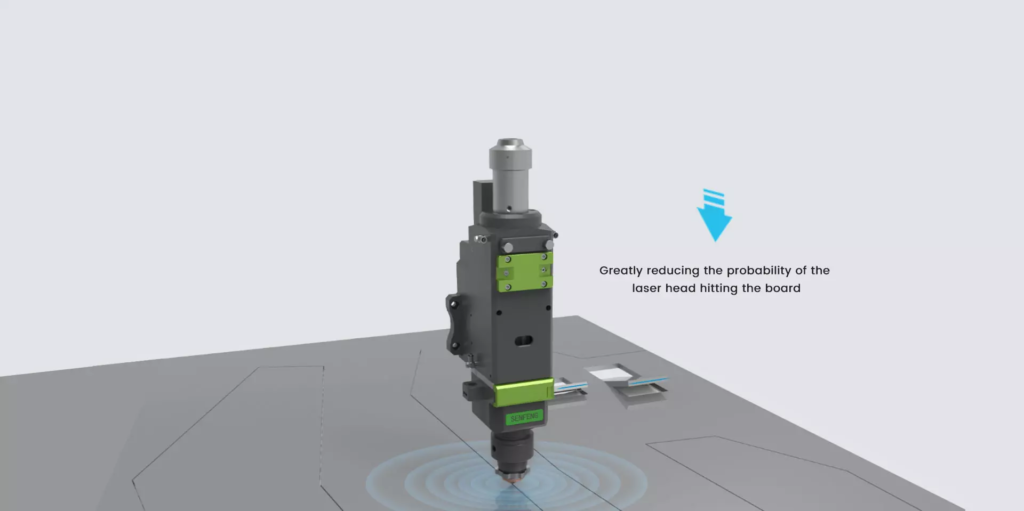

Autofocus Laser Head

Laser head with reinforced cover, resilient in high pressures, automatic control system and intelligent barrier avoidance system to ensure cutting quality and longer lens life.

Autofocus Technology

For cutting 6mm or more carbon steel thickness, the laser autofocus reduces the drilling time by 1/2, for cutting 16mm or greater the drilling time will be reduced by 2/3.

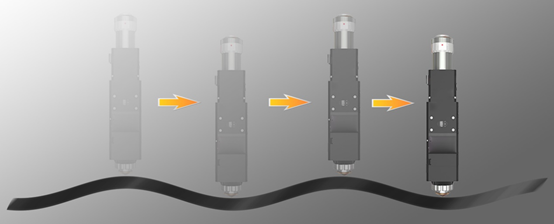

intelligent obstacle avoidance.

Automatic Focus Height Guide

- A U.S.-imported technology patent that has been adopted and improved by China.

- The automatic sensor understands the capacity between the edge of the isolated nozzle and the surface of the cutting sheet and channels the data to the height monitor.

- If the metal sheet has ripples on its surface, the focus height guide can ensure a constant distance between the focal lens and the respective level of the metal cutting sheet so that consistent cutting quality can be achieved.

- Therefore this technology can avoid defects caused by wavy metal surfaces and also avoid any damage that may be caused to the head nozzle.

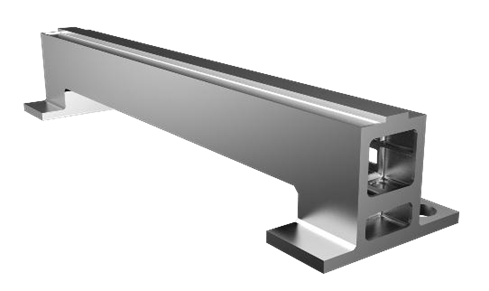

Cast Aluminum Beam

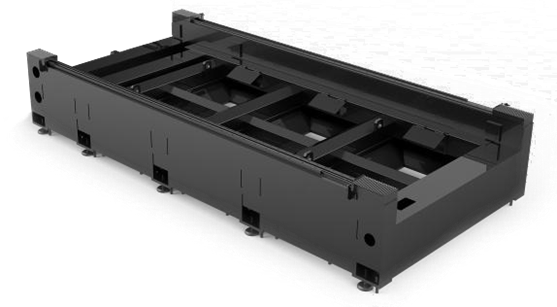

Carbon Steel Special Design Table

Table features:

High strength, good stiffness, long-term operation of the table without distortion, high processing accuracy.

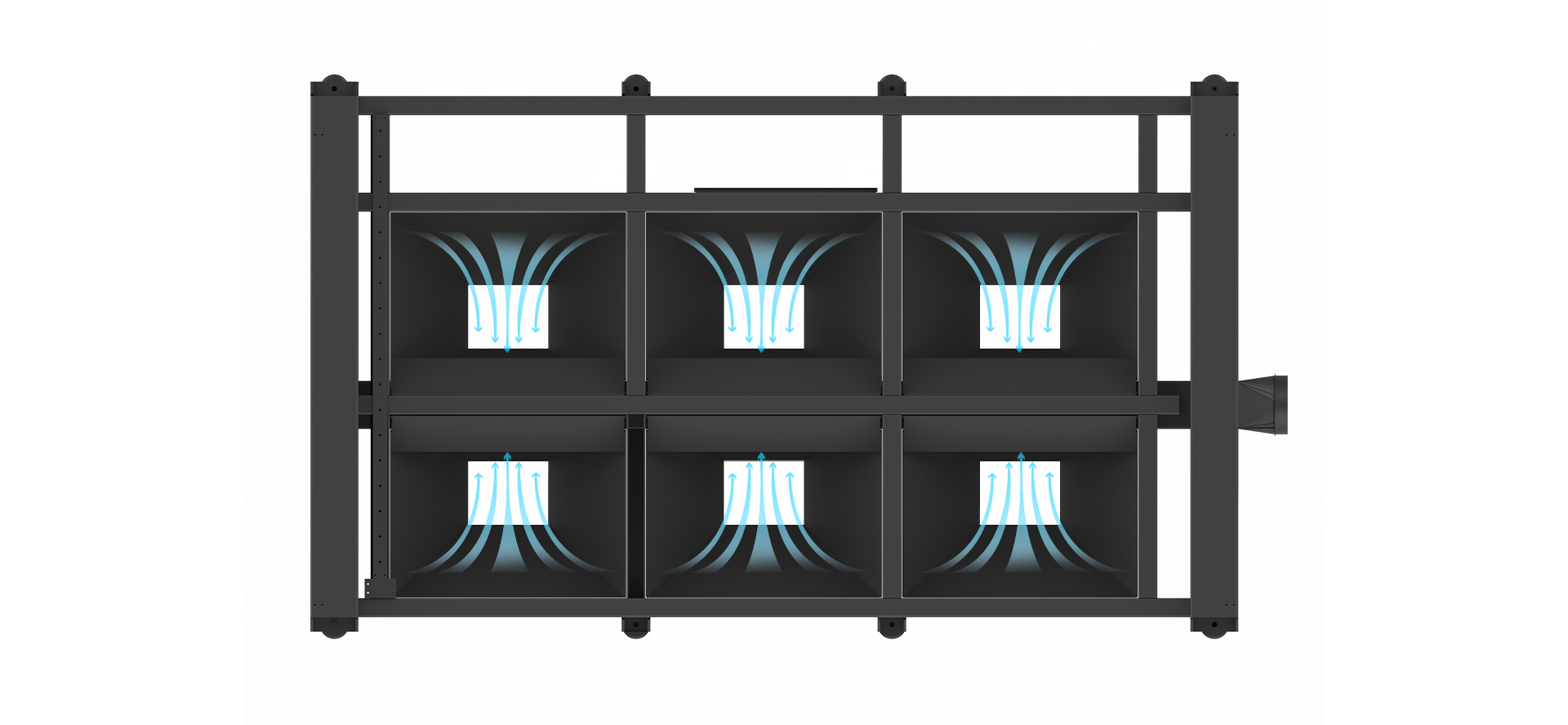

Exhaust system.

Double Upper and Lower Evaporation System for smoke absorption

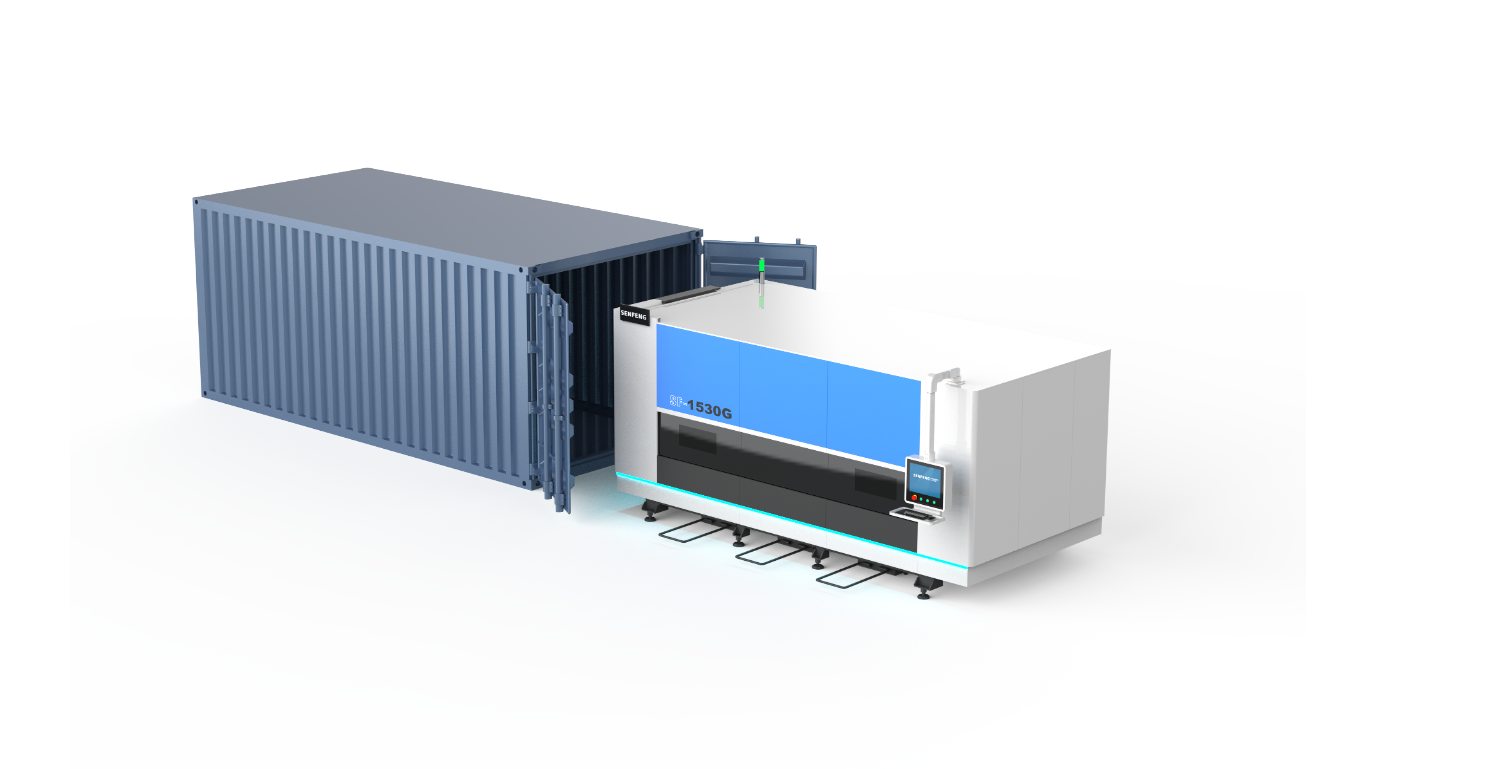

No Need To Dismantle The Machine For Delivery

Whole machine fit into a 20-foot container.

Single Working Area, Manual Pull-out Type

Safe And Environmentally Friendly